Understanding the basics of LVL formwork timber

When it comes to construction materials, few options can match the versatility and reliability of LVL (Laminated Veneer Lumber) formwork timber. This engineered wood product is increasingly favoured in various construction projects due to its incredible strength and stability. Understanding the basics of LVL formwork timber will help you appreciate why it’s such a popular choice in the industry.

What is LVL formwork timber?

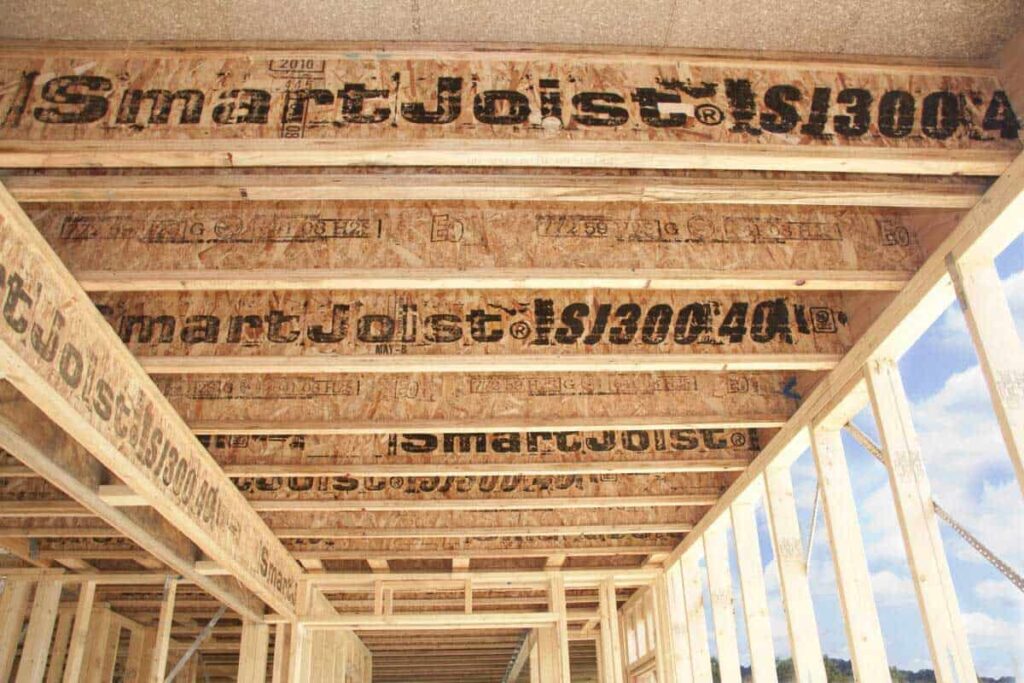

LVL formwork timber is an engineered product made from thin layers of wood veneer that are glued together under heat and pressure. The result is a strong, homogeneous material that exhibits superior qualities compared to traditional solid wood. Because it is manufactured from several layers, LVL is designed to withstand loads and stresses that are common in construction applications.

This material is predominantly used for formwork in concrete applications, where the ability to support heavy loads and maintain accuracy is crucial. With its reliable properties, LVL formwork timber has become essential for builders and contractors looking for efficient and sturdy solutions.

The unique properties of LVL formwork timber

One of the standout features of LVL formwork timber is its impressive load-bearing capacity. Not only does it resist bending and warping, but it also maintains its integrity under varying weather conditions. Unlike traditional timber, LVL is less likely to be affected by moisture, making it ideal for use in construction sites where humidity can be a concern.

Moreover, LVL is consistent in strength and performance, which contributes to better planning and execution of construction projects. Its uniformity leads to less waste and a more sustainable building process, advantages that every contractor can appreciate.

The production process of LVL formwork timber

Understanding how LVL formwork timber is produced gives us greater insight into its strength and stability. The production process is a blend of modern technology and traditional woodworking, resulting in a superior building material.

Read about lvl formwork prices at: Comparing Timber LVL Formwork Prices

Raw materials used in LVL formwork timber

The primary raw material for LVL timber is wood, typically sourced from fast-growing tree species such as pine, eucalyptus, or fir. These woods are ideal because of their balance of availability, strength, and cost-effectiveness. Manufacturers select high-quality logs to ensure that the resulting product meets stringent performance standards.

Furthermore, adhesives used in the layering process are crucial. These are specially formulated to bond the layers effectively while providing resistance to environmental factors such as moisture and temperature changes. Read more about moisture at https://people.umass.edu/~mcclemen/581Moisture.html

The manufacturing steps of LVL formwork timber

The manufacturing of LVL formwork timber involves several critical steps. First, the logs are processed to remove the bark and cut into veneers. These veneers are then dried to a controlled moisture content, ensuring optimal bonding conditions.

Next, the dried veneers are coated with a durable adhesive and laid out in layers. Once stacked, they are pressed together under high pressure to cure the adhesive. This creates a solid block of timber that is then cut into various sizes and shapes, tailored to specific construction needs.

Finally, the LVL is finished with treatments to enhance its durability and resistance to decay and pests, making it a reliable choice for long-term use in construction.

The strength and stability of LVL formwork timber

The hallmark of LVL formwork timber lies in its inherent strength and stability. Understanding how these qualities are achieved helps us appreciate its application in construction projects.

How LVL formwork timber achieves its strength

The strength of LVL timber is primarily due to its layered construction. By aligning the grain of the veneers, manufacturers can create a material that resists bending and shearing forces more effectively than standard timber. This engineered approach ensures that LVL can support heavy loads, making it perfect for formwork in concrete settings. Click here to find more about forces.

Additionally, LVL’s consistent material properties mean that it can be designed and utilised to specific load-bearing requirements, enhancing safety on construction sites.

The stability factors of LVL formwork timber

Stability is another critical factor that makes LVL an excellent choice for formwork. Unlike solid timber, which can warp and twist over time, LVL maintains its shape, ensuring that construction projects progress without unnecessary delays.

The adhesives used in production also play a vital role in enhancing stability. They mitigate the effects of moisture and temperature changes, enabling LVL timber to perform reliably in diverse climates.

The applications of LVL formwork timber in construction

LVL formwork timber has a myriad of applications in construction, making it a beloved material among builders and architects alike. Its adaptability allows it to be employed in various contexts, from residential projects to large commercial endeavours.

Residential construction uses for LVL formwork timber

In residential construction, LVL is commonly used for creating formwork for foundations and structural supports. Its ability to handle heavy loads is beneficial for basements, retaining walls, and other crucial structures. Moreover, because it is predictable in its behaviour, builders can work with LVL timber confidently, knowing that their projects will stand the test of time.

Beyond foundations, LVL is also ideal for beams and columns, where strength is non-negotiable. Architects can incorporate LVL into designs that require expansive open spaces without compromising structural integrity.

Commercial construction uses for LVL formwork timber

In the realm of commercial construction, LVL formwork timber finds its place in high-rise buildings, bridges, and sports complexes. Its durability and load-bearing capabilities make it suitable for significant infrastructure projects where failure is not an option.

Additionally, contractors appreciate the ease of use and quick installation that LVL provides, which can lead to faster project completion times. This efficiency often translates into cost savings for developers and builders.

The environmental impact of using LVL formwork timber

As sustainability becomes an increasingly important consideration in the construction industry, LVL formwork timber stands out for its environmentally friendly attributes. Its production and use carry significant advantages in terms of reducing the overall carbon footprint of construction processes.

Sustainability considerations of LVL formwork timber

LVL timber is often made from sustainably managed forests, ensuring that timber resources are not depleted. This responsible sourcing contributes to the conservation of forests and biodiversity while supporting local economies. Furthermore, because LVL is an engineered product, it maximises the use of timber resources, reducing waste.

By choosing LVL formwork timber, builders help reduce the environmental impact associated with traditional construction methods, promoting a more sustainable future in the building industry.

The lifecycle of LVL formwork timber

The lifecycle of LVL formwork timber is an important factor to consider when evaluating its environmental impact. From production to disposal, LVL timber provides a positive scenario for sustainability. When the timber reaches the end of its life, it can often be recycled or repurposed, minimising waste.

Moreover, as an engineered product, LVL often outlasts standard timber in various applications, further reducing the need for replacements. This longevity substantially lowers the demand for new materials, further enhancing its eco-friendly profile.